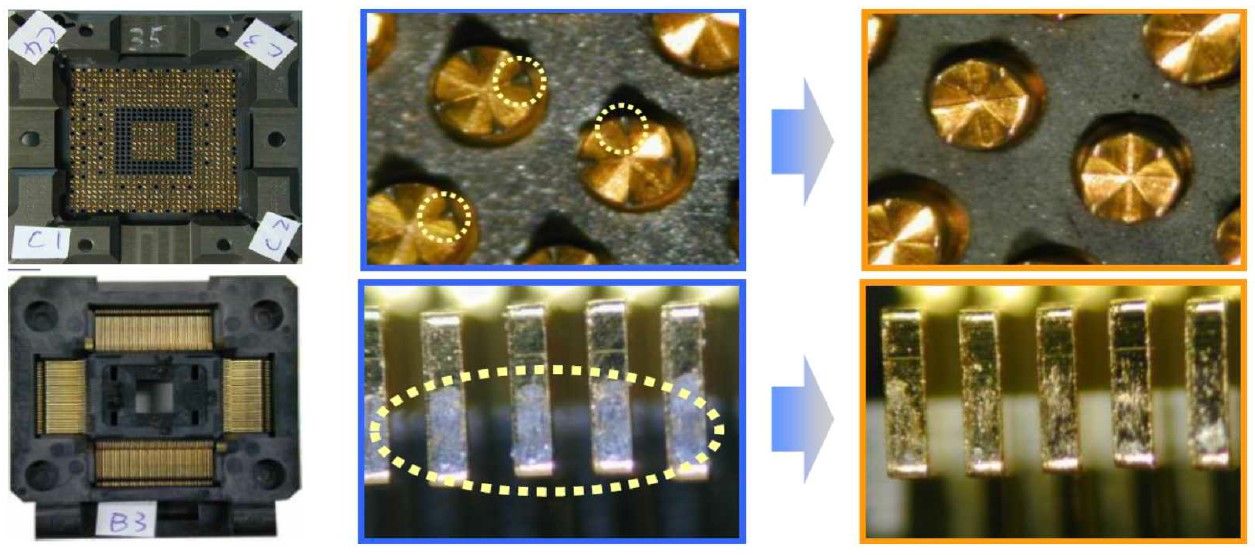

Laser Cleaning System for E-test Jig Clean

Lasers are used for non-contact cleaning

- Laser selection (appropriate wavelength)

- Suction while hitting (to avoid secondary pollution)

- Surface cleaning (non-production equipment)

Equipped with galvanometer system for automation purposes

- High efficiency (programmable)

- Automation (traceable)

- Simplicity (User-Friendly)

Easy to Operate

The fixture is easy to set up, and there is no need to disassemble the fixture head; With a semi-automatic architecture, the cleaning, method can be range scanning, or manual single point, and the fixture cleaning can be easily completed.

Data-based Management

The cleaning parameter can be stored according to the fixture number, with the hierarchical management of authority, and the relevant resume (production, maintenance, alarm) can be output, which is suitable for on-site design and planning.

Easy to Use

Confined space design, with efficient dust collection system, to avoid secondary pollution.

Equipped with dual CCD, the cleaning range can be checked before operation, and the cleaning effect can be checked after operation, and all of them can be completed on the equipment after getting on the machine, which is easy to operate.

To remove Tin (Sn) based contamination from pogo-pin surface.